Overview

- The Problem

- Tools, Skills And Parts

- Preparations

- Removing Brake Pad Carrier

- Mounting Brake Pad Carrier

- Tightening Torques

The Problem

The reason behind replacing a brake pad carrier can be several.

But in this case it was due to a broken brake caliper guide bolt

where a small part of the bolt remained in the brake pad carrier

(on which the brake caliper is mounted on). A quick and easy solution

is to simply replace the entire brake pad carrier.

Tools, Skills And Parts

The job is pretty straightforward and does not include any

special tools.

Difficulty Level

The following tools are required for this particular work (tools marked with

green checkmark are optional).

| Jack | |

| Jack pad liners | |

| Jack stand | |

| Screwdriver (flat-blade, 3.5 mm) |

| Wheel nut wrench (17 mm) | |

| Tire lever (small) | |

| Ratchet wrench (15 cm, small) |

| Socket extension bar (10 cm) |

| 7 mm Allen key socket | |

| 19 mm 6-point socket | |

| Torque wrench |

| Disc brake pad spreader | |

| Brass brush |

| CRC Copper paste | |

| CRC 5-56 | |

| CRC Bräkleen | |

The following spare parts are required for this particular work. Note

that the BMW internal numbers are intended for a BMW 535i E34 -89.

| brake pad carrier | 34 11 1 160 366 |

Preparations

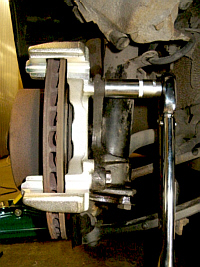

The brake pad carrier is mounted with two large 19 mm hex head screws directly on the front

strut assembly. The brake caliper is then mounted onto this brake pad carrier using two 7 mm Allen

key guiding bolts. To ease the work of loosening the two 19 mm hex head screws it is recommended

to soak down the area around these two screws with CRC 5-56 or similar and let it stay and penetrate

over the night. See the picture below for the location of the two screws.

The front right strut assembly, brake pad carrier and the brake disc. Note that the brake caliper

has been dismounted and moved out of the way. The 19 mm hex head srews holding the brake pad

carrier are marked in the picture.

Removing Brake Pad Carrier

Start by jacking up the car, remove the wheel and the brake caliper. This is described

in detail in the brake pad replacement job. It is now time to try to loose the two screws

holding the brake pad carrier. It may require quite a lot of force to loosen these screws

but with the right tools it shouldn't be any problem. It is strongly recommended to only

and only use 6-point sockets (or wrenches). Using 12-points sockets (or wrenches) will

only transform the hex shape into round shape, especially when the bolts and screws are

sitting tight as it can be in this case.

After the screws have been loosened, remove them completely together with the old

brake pad carrier. The view at the front strut assembly should now look like the

picture below.

The front right strut assembly with the brake caliper and brake pad carrier removed.

|

Mounting Brake Pad Carrier

It is now time to unpack your absolutely fresh brake pad carrier. Below is a series

of pictures illustrating how this piece looks like when it is completely new.

An absolutely fresh brake pad carrier.

An absolutely fresh brake pad carrier.

An absolutely fresh brake pad carrier.

Start by cleaning the two large 19 mm hex head screws using brass brush and cotton waste

for example. Add a thin thin coat of copper paste on the threads. Mount the new brake pad

carrier with the two cleaned screws and use a torque wrench as the last step. See the picture

below for an example and the table at the end of this article for torques.

The upper 19 mm hex head screw holding the brake pad carrier tightened with a torque wrench.

The job is almost finished now. Optionally clean the brake disc with CRC Bräkleen or

similar to remove oil, grease and deposits. The remainder of the installation is the reverse

of removal.

The new brake pad carrier mounted looking shiny and new!

Tightening Torques

| Brake caliper to brake pad carrier (guide bolt) | 35 Nm (26 ft-lb) |

| Brake pad carrier to front strut assembly | 110 Nm (81 ft-lb) |

| Road wheel to hub | 100±10 Nm (74±7 ft-lb) |

|